Fibreglass mesh reinforced plasters and specific mortars for repairing and strengthening masonry structures.

The advantages of the system

The G-MESH 400/490 system represents the transition from the traditional reinforced plaster, electrowelded steel mesh and cementitious plaster technique, to the CRM (Composite Reinforced Mortar) system, through the use of preformed meshes in resistant alkali composite material that prevent corrosion of the strengthening elements while offering excellent mechanical performance.

High tensile elastic modulus and excellent mechanical strength performance.

The wide range of structural mortars, based on highly pozzolanic hydraulic binder, based on NHL 3.5 natural hydraulic lime, based on cement, and the choice of various connection systems make the G-MESH 400/490 system extremely versatile and ideal for every need.

High compatibility with masonry, it can also be used with natural hydraulic lime-based mortar MX-CP Lime, making it ideal for historical-monumental buildings.

The G-MESH 400/490 meshes, supplied in rolls of 40 m2 are highly manageable. Installation is quick and easy, thanks to the relative rigidity of the materials, and the fact that the structural mortars may be applied manually or mechanically, depending on the needs of each construction site.

G-MESH 400/490 meshes boast excellent performance in alkaline environments (with both lime and cement-based mortars) thanks to the alkali-resistant properties of the glass; the preformed GFRP meshes ensure stresses are transferred uniformly to the entire system and, thanks to the epoxy resins used in their construction, the meshes are ideal for preserving the final properties of the composite.

Perfectly compliant with the Guidelines introduced in May 2019 for the identification, performance testings and acceptance control of preformed mesh systems in polymer matrix fibre-reinforced composite materials for structural strengthening of existing buildings using the CRM reinforced plaster technique.

Italian Ministerial Decree of 28/05/2020 extended the qualification of preformed mesh systems for obtaining ETA or CVT certification by a further 12 months (May 2021).

Fields of application of the system

For strengthening existing solid brick, tufa, and irregular stone masonry.

Static and seismic retrofitting and upgrading existing load-bearing masonry buildings.

Ruregold reinforced plaster is realized using the CRM masonry strengthening system, consisting of the following elements:

- preformed meshes in G– 400/490 MESH alkali-resistant impregnated fibre glass;

- connection system consisting of HELICAL CONNECTOR helical, stainless steel bars or, alternatively, G-MESH CONNECTOR preformed, A.R. glass fibre elements;

- G-MESH GUSSET thickening gussets positioned in correspondence with the connection systems;

- structural plaster mortars based on high-pozzolanicity hydraulic binder MX-RW High Performance, based on lime MX-CP Lime and based on cement MX-15 Plaster, obtained by means of premixed and pre-dosed technologies.

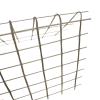

Fibre glass plaster support mesh, grammage 400 g/m2.

80×120 mm mesh.

Fibre glass plaster support mesh, grammage 490 g/m2.

80×80 mm mesh.

Complementary products

Stainless steel bar for connection systems.

Preformed GFRP alkali-resistant impregnated glass fibre connection element.

Grammage 490 g/m2. 80×80 mm mesh.

Preformed element in A/R fibre glass to be applied in correspondence with the CONNECTORS.