When it was inaugurated, in 1936, the

Thurgood Marshall Federal Courthouse was the tallest public building in the United States.

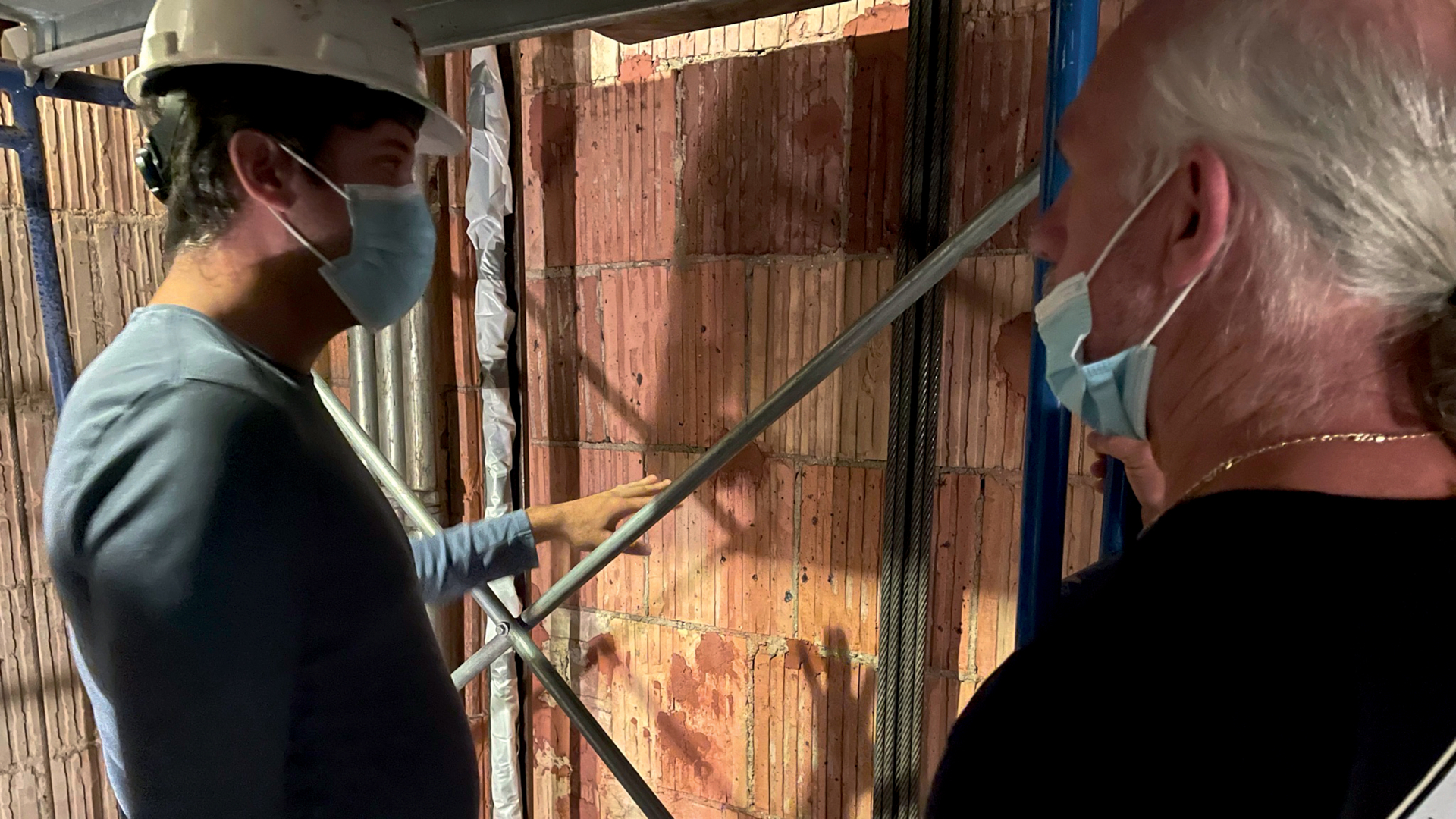

In 2021, the building, consisting of a 33 storey tower, was the subject of

large-scale renovation, work being carried out on the granite facades and the striking golden pyramidal roof, as well as the various fire prevention and

safety systems, the entrances, stairways and

lift shafts.

The latter presented evidence of deterioration attributable to the effects of water infiltration and vibration.

Due to the unusual context in which the work needed to be carried out, coupled with the need limit the length of time the systems would be out of service, the works management opted for a solution that involved

strengthening the masonry structures of the lift shafts based on Ruregold’s

FRCM composite material solutions.

Given the specific nature of this application, it was decided to adopt

C-Mesh 84/84, consisting of the bi-directional carbon fibre mesh (84+84 g/m2) and the

MX-C 25 Masonry inorganic matrix, together with

C-JOINT Carbon fibre connector.

C-JOINT is the carbon fibre anchoring element used to connect

masonry and

reinforced concrete structures. The fibre connector is

prepared on site and consists of a bundle of continuous parallel fibres or strands bound within a tubular elastic net made of polyester, polyamide and latex fibres. The mesh can be extended both longitudinally and transversely, and may also be removed.

The bundle only becomes rigid once it has been impregnated with the specific inorganic matrix

MX-JOINT, and inserted into the respective holes that have been pre-drilled on the structural element.

The system is used for

applications on masonry, such as

wrapping or

shear and flexural strengthening and, thanks to the high grammage of the carbon fibre mesh and the high performance of the organic matrix, it

can be used to increase the capacity of structural elements to resist in and out of plane actions as well as the

ductility of masonry buildings,

guaranteeing high reliability thanks to its post-cracking response under detachment conditions.

Resistant to freeze-thaw cycles and high temperatures, the C-Mesh 84/84 system may also be applied on damp supports without the need for special protections.

The

ease of use and

reliability of the inorganic matrix, which is laid using the same techniques as cementitious mortar, represent advantages that are

unique to FRCM structural strengthening systems.