Fibre-reinforced concrete (FRC) is a composite material characterised by a cementitious matrix and discontinuous fibres, which has been used successfully in numerous structural applications, from construction to infrastructure, thanks to the countless properties conferred on the cement mix by the addition of fibres.

Classification of FRCs

Fibre-reinforced concrete is grouped into the same compressive strength classes as traditional concrete. Structural concrete can be classified as follows:

• Normal performance resistance ratings not exceeding C45/55.

• High performance ratings up to C70/85.

• High resistance ratings between C70/85 and C90/105.

• The performance of resistance ratings exceeding C90/105 (UHPC) has not yet been taken into account by the current regulatory environment.

If quantities of fibre ≥ 0.3% by volume are associated with the performance of the cementitious matrix, the concrete can be classified as follows:

• FRC (Fibre Reinforced Concrete).

• HPFRC (High Performance Fibre Reinforced Concrete).

• UHPFRC (Ultra High – Performance Fibre Reinforced Concrete).

This category includes Micro Gold Steel, which is classified as HPFRC: high performance and fibre-reinforced concrete.

Applications

Construction:

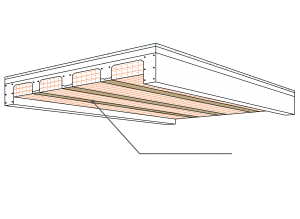

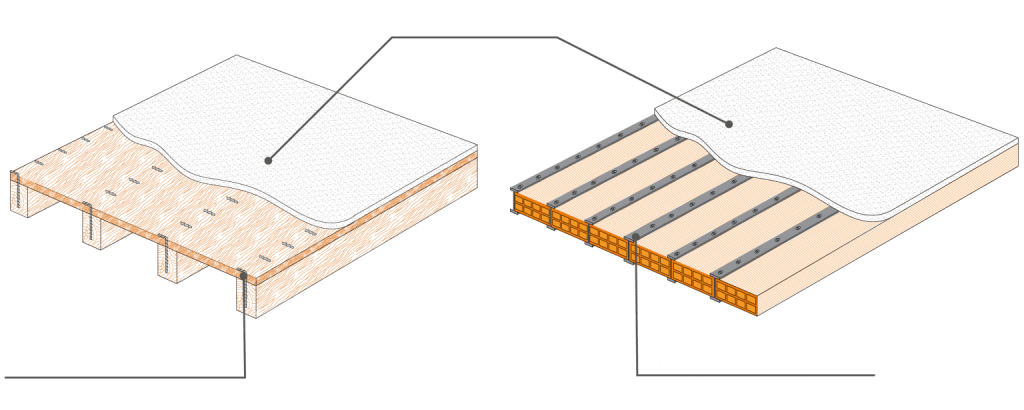

• Low-thickness structural repair of slabs in steel and timber

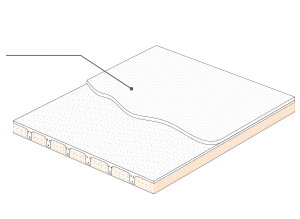

• Low-thickness static strengthening of concrete slabs

• Structural strengthening of columns with jacketing

During structural repair of steel and timber slabs, applying HPFRC micro-concrete to the slab extrados (upper side) using a suitable mechanical connection system, offers numerous advantages:

• increases the load-bearing capacity of the deck

• Allows low thickness application

• Ensures high mechanical compressive and flexural strength

During low-thickness static strengthening of concrete slabs, HPFRC micro-concrete can be applied at low thicknesses, including on the slab extrados (upper side) even without the application of connection systems and extensive reinforcement. It increases the rigidity of the median plane of the slabs, ensuring high performance, and fast, simple application

In the case of jacketing, using high-performance, fibre-reinforced concretes make it possible to reduce the thickness of the jacket applied to the original column, also effectively reducing the need for additional strengthening, while guaranteeing significantly higher performance of the reinforced element. The addition of fibres modifies the mechanical properties of the concrete, significantly improving its tensile behaviour and, above all, contrasting the onset of cracking.

Infrastructure:

• Structural repairs by bolstering bridge piles

• Structural strengthening by repairing the slab extrados (upper side)

In addition to reducing the number of rebars necessary, using micro-concrete to bolster bridge piles ensures the reduction of cracks during the plastic shrinkage of the conglomerate, as well as improved behaviour at the limit of operation and greater mechanical resistance.

The high tenacity conferred on the conglomerate by the presence of metal fibres, the excellent adhesion to existing concrete and to concrete rebars (which may be passivated if necessary), and the resistance to freezing and thawing cycles, render micro-concrete the ideal solution for repairing the slab extrados (upper side) during structural strengthening of infrastructure.