HPFRC Micro-concretes

fibre-reinforced with steel fibres for structurally strengthening

pillars, columns, beam-column nodes and top strengthening concrete layers.

The characteristics of FRC and HPFRC concretes

Fibre-reinforced concretes (FRC) are now widely used in numerous structural applications, where they have taken supplanted (either partially or completely) traditional reinforcements.

This means that the designer can plan the work to be carried out in the knowledge that they are using a material having structural characteristics that differ with respect to normal concrete.

FRC concretes are composite materials consisting of a cementitious matrix (concrete or mortar) with the addition of short steel or synthetic fibres. Depending on the type of structural element where the work is to be carried out, these may be augmented by the use of ordinary or pre-compression reinforcements.

The addition of dispersed fibres to a cementitious type matrix modifies its mechanical properties.

The purpose of the fibres is to contrast the progressive widening of cracks by conferring significant residual tensile strength on the concrete post-cracking (toughness of FRC concrete).

The residual tensile strength, and hence the specific energy required to rupture the conglomerate via, or reach levels sufficient to widen the predetermined cracks, depends on several factors, as follows:

-

the aspect ratio of the fibre;

-

the percentage of fibre by volume with respect to the total volume of the composite;

-

the physical-mechanical characteristics of the fibres;

-

the physical-mechanical characteristics of the cementitious matrix.

Thus the fibres are able to exert their influence by conferring on the composite a post-cracking resistance that is absence in non-fibre reinforced matrices, thanks to the development of widespread cracking within the matrix.

FRCs are classified as follows:

- standard performance, for compressive strength up to C45/55;

- high performance, with compressive strength up to C70/85;

- high resistance, with compressive strength greater than C70/85 and up to C90/105;

- in the case of compressive strength ratings of greater than C90/105, the UHPC performance specifications are not covered by the current regulatory framework.

Concretes belonging to resistance classes listed above and characterised by a structural fibre content of greater than 0.3% by volume may be classified as follows:

- FRC (Fibre Reinforced Concrete);

- HPFRC (High Performance Fibre Reinforced Concrete);

- UHPFRC (Ultra High – Performance Fibre Reinforced Concrete).

This classification includes Ruregold’s Micro Gold Steel concrete, which is classified as HPFRC: high performance and fibre-reinforced.

Applications for HPFRC Micro-concretes

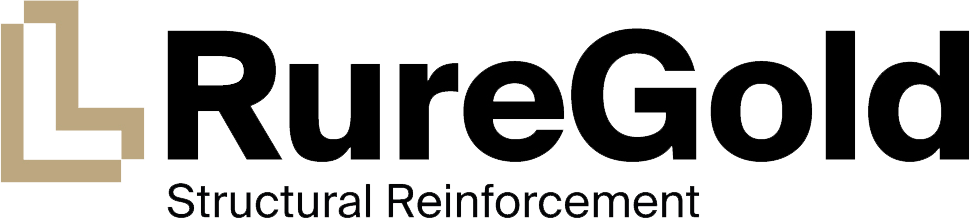

Strengthening beams

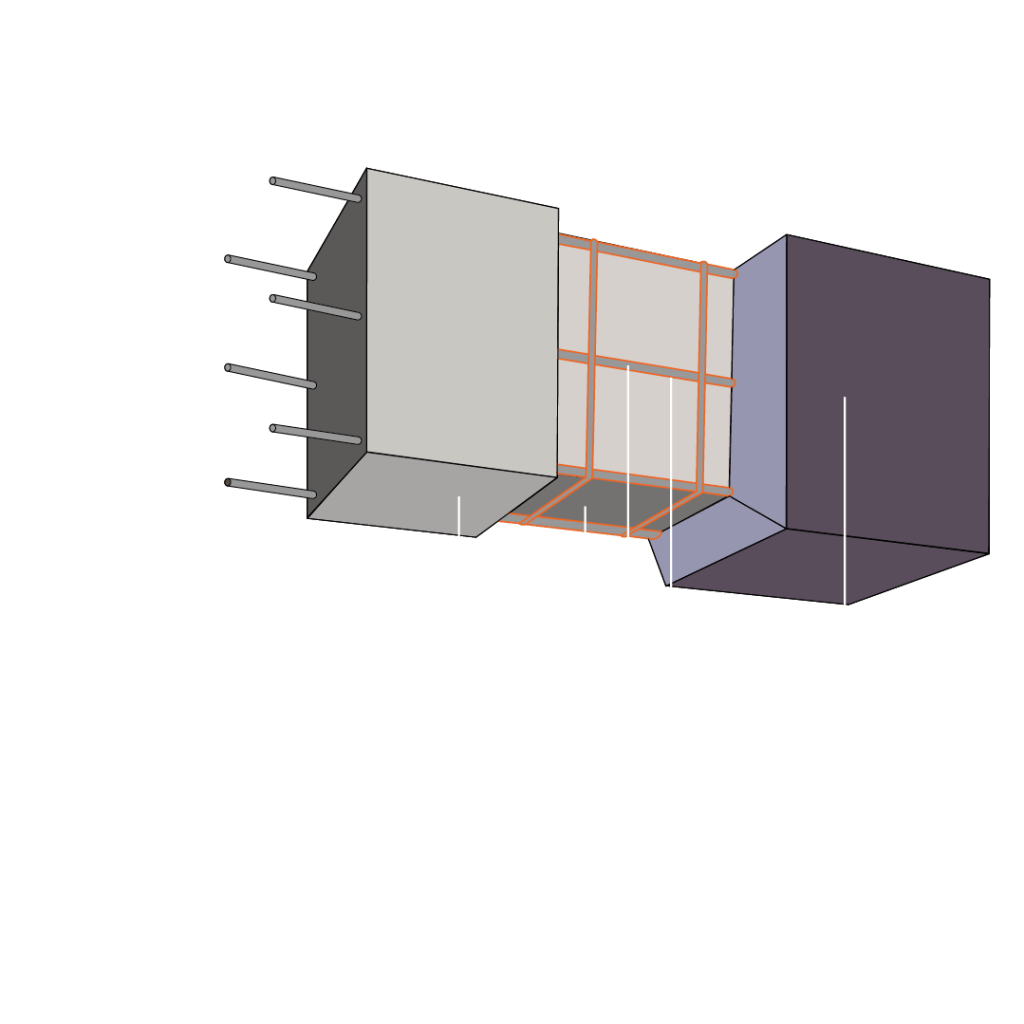

Strengthening columns

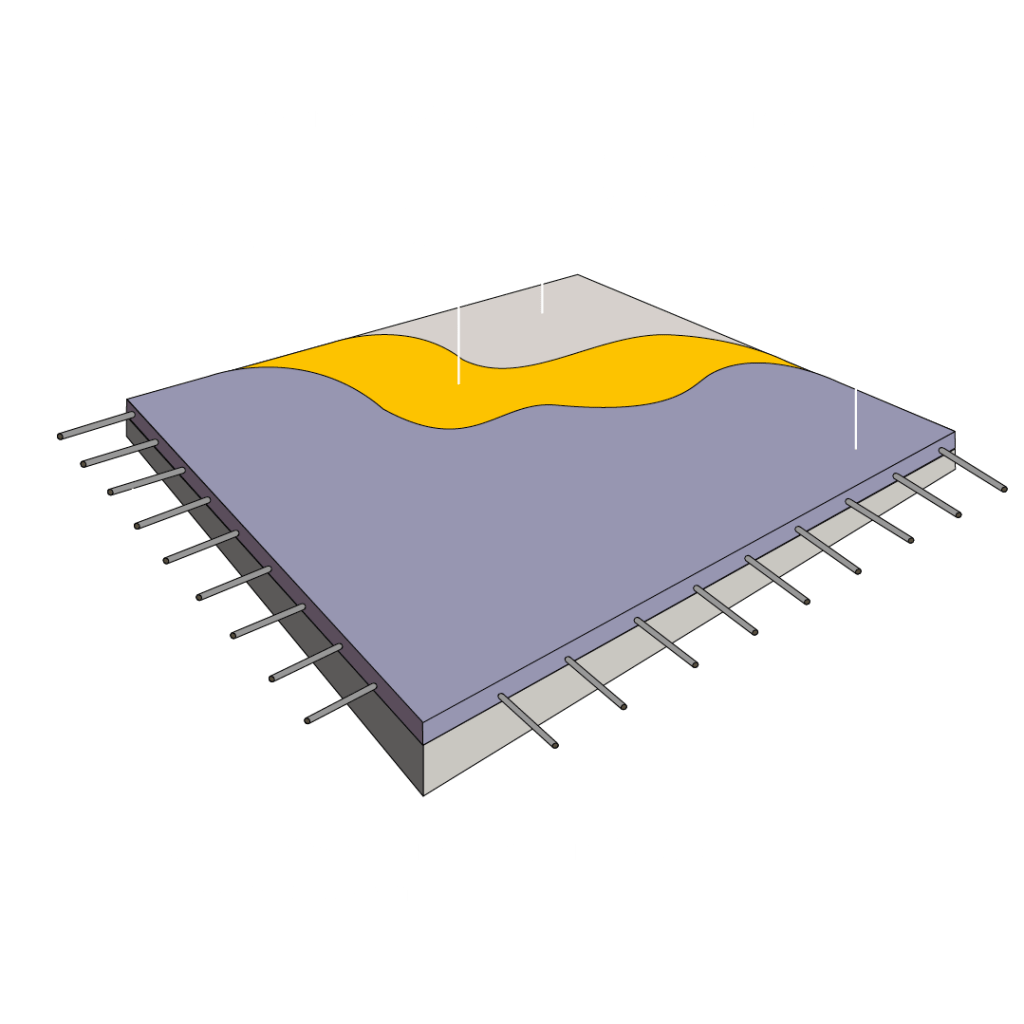

Strengthening collaborating top concrete slabs

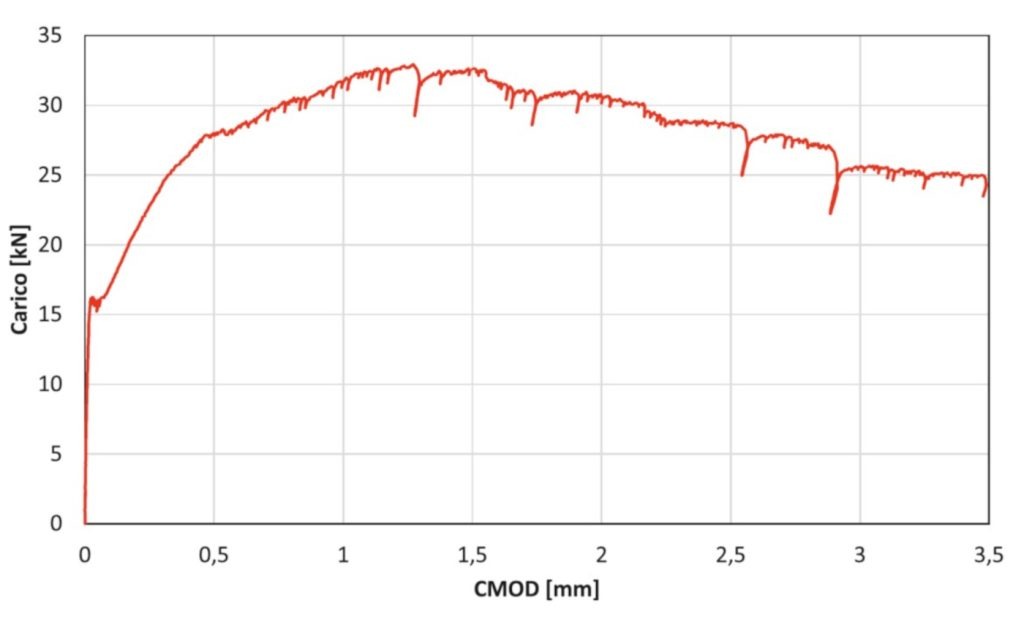

Experimental load/strain curves and residual tensile strength

The following is a series of residual tensile strength curves obtained for Micro Gold Steel and FCC respectively, during the ministerial evaluation process.

It should also be noted that Ruregold Micro Gold Steel passed a series of additional test regarding adhesion following freeze/thaw treatment with de-icing salts, which represents a particularly important parameter in the ambit of infrastructure.

MicroGold Steel CMOD characterisation

The summary table compares the residual tensile strength by bending values – fRj (MPa) of the various products.