Shatter and falling of ceiling fragments: causes and solutions.

Discover the features and advantages of certified ceiling anti-shatter systems.

Shatter and falling of ceiling fragments occurs when, in the case of brickwork slabs or concrete beam and block floor, mortar, plaster and hollow-core infill blocks become detached from the ceiling with the risk of falling. To render buildings safe against this phenomenon, Ruregold has developed a series of ceiling anti-shatter protection solutions.

The buildings most at risk are those built between the 40s and 70s, due to the type of brick used: these include school buildings, public buildings, hospitals, condominiums and individual private homes.

More specifically, the phenomenon of "shatter and falling of ceiling fragments" involves the lower panels becoming detached from the lightening blocks inserted in mixed concrete beam and block floor and falling to the ground.

The detachment of the lightening elements, whether or not they are load-bearing, may endanger people and adversely affect the ambient conditions in environment where the phenomenon occurs.

For this reason, it is important to solve the problem by implementing an appropriate solution

Intervening effectively against shatter and falling of ceiling fragments

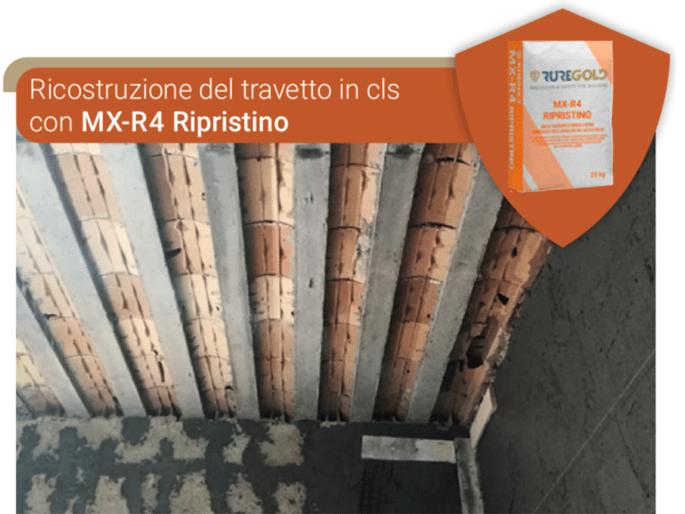

Before carrying out any ceiling anti-shatter work, we strongly recommend checking the condition of the reinforced concrete joists.

In the event of certain level of deterioration, it is necessary to intervene as a matter of priority:

- reinforcements, remove the discontinuous parts, brush the bars and treat by Passivating.

- Concrete cover, restore the geometry of the concrete joist using MX-R4 Repair controlled shrinkage fibre-reinforced thixotropic mortar, certified in accordance with UNI EN 1504-3.

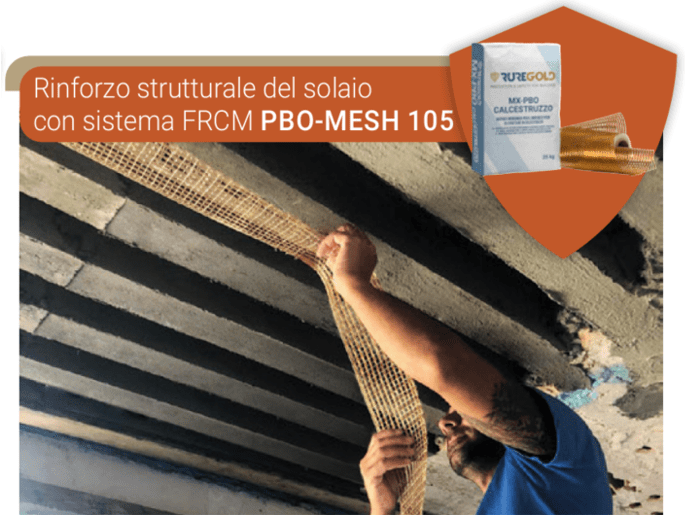

If it is necessary to integrate the reinforcements, intervene using the Ruregold FRCM structural strengthening system, consisting of PBO-MESH 105 mesh and MX-PBO Concrete inorganic matrix.

Discover Ruregold's three ceiling anti-shatter systems

THE SAFENET SYSTEM

THIS IS THE MOST EFFICIENT, PRACTICAL AND EASY TO INSTALL thanks to the reduced number of anchoring points

SafeNet is safe, quick and easy to apply: simply position the mesh on the intrados (lower side), secure it with one of the anchoring systems and finish using SafePlaster premixed plaster.

THE SYSTEM IS LOAD-SAFE AND CERTIFIED for overloads of 500 kg/m2, with various anchor point distribution patterns and in the presence of suspended loads (lighting systems and other accessories).

IT IS SIMPLE AND QUICK TO INSTALL and guarantees excellent adhesion to the existing support (concrete, plaster, brick) and easy pumpability with traditional plastering machines. The plaster may be left exposed or finished with skim coat according to preference.

SUITABLE FOR ALL TYPES OF SLABS, the system adapts perfectly to the different types of slabs (brickwork, SAP, Varese, etc…), thanks to the range of structural and non-structural fastenings.

IT CAN ALSO BE DRY LAID, as a preventive measure, the system can be applied dry or left exposed. Installation is simple and quick, guaranteeing ceiling anti-shatter load performance of up to 250 kg/m².

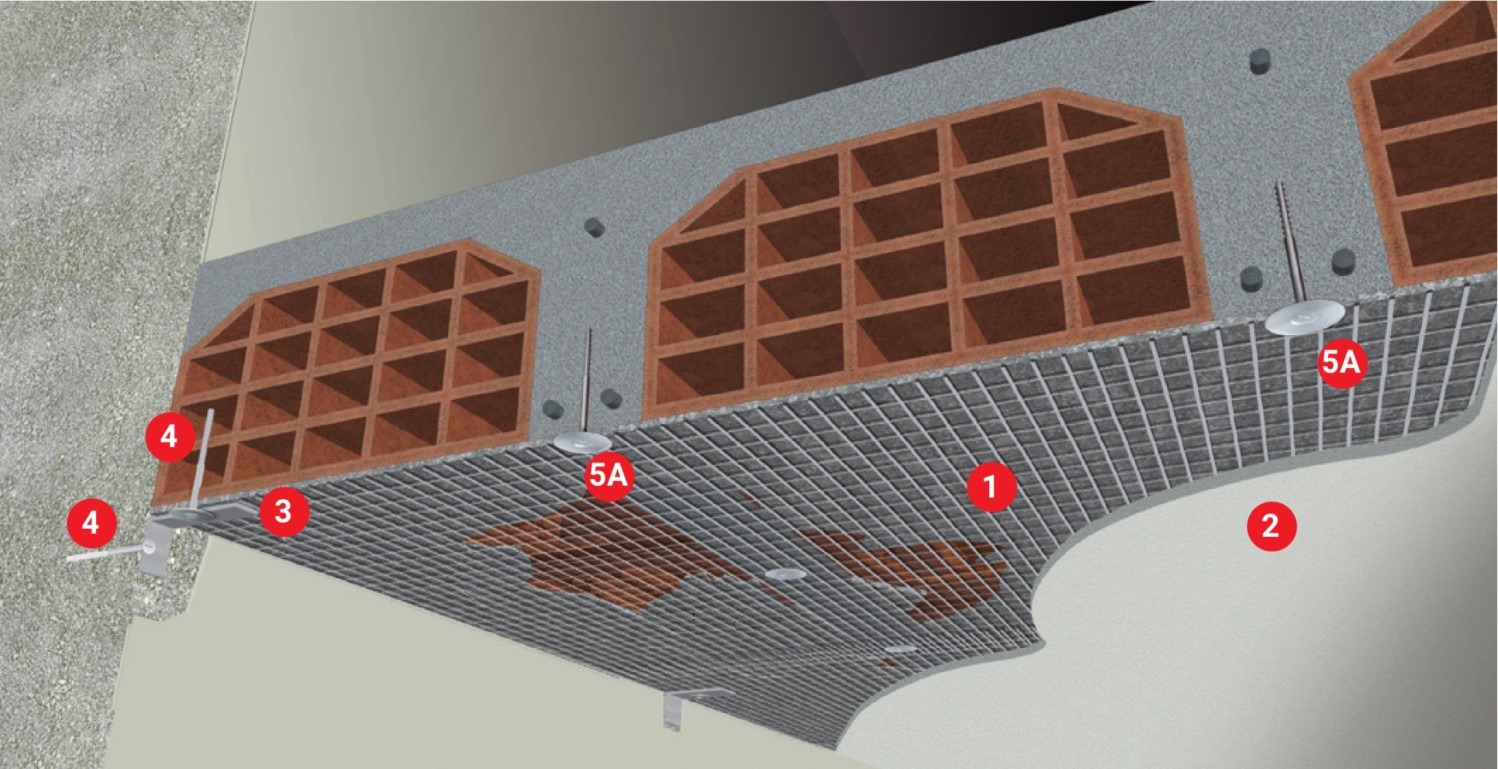

SYSTEM COMPONENTS

1 – SafeNet A/R fibreglass mesh

2 – SafePlaster, fibre-reinforced, reduced shrinkage premix

3 – Angular plate, "L" shaped for perimeter securing Armanet-Stucanet meshes, applied using Nylon anchor.

4 – Nylon expansion anchor, supplied with dedicated steel washer and SBR coupled, for non-structural fastening of SafeNet-Stucanet-Armanet meshes in concrete joists.

5A – Steel concrete screw, supplied with washer, for structurally fastening SafeNet in the concrete joist

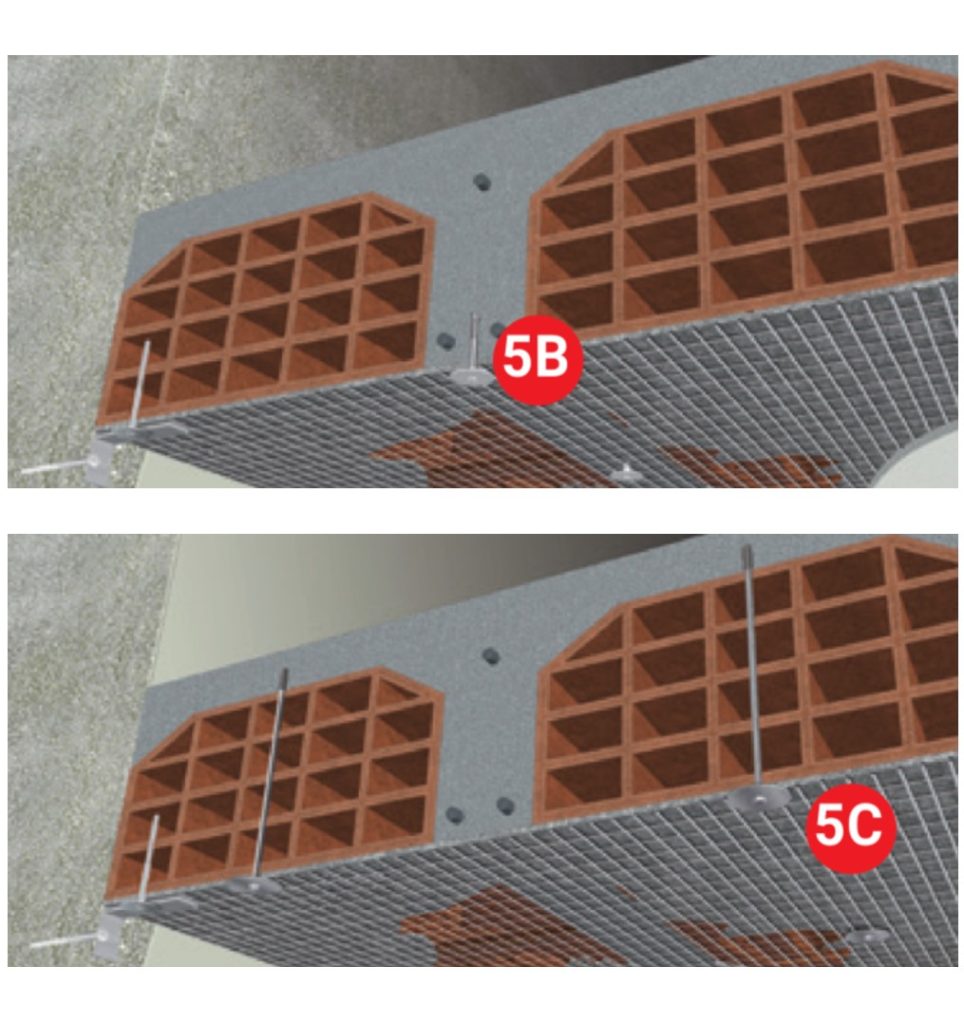

5B – Steel concrete anchor, supplied with washer, for structurally fastening SafeNet in the concrete joist.

5C – Steel concrete through-anchor, supplied with threaded rod, washer and self-locking nut for structurally fastening SafeNet in the slab cover

THE STUCANET SYSTEM

SPECIFIC FOR BADLY SHATTERED OR FALLEN SLABS because it does not require preparation of the support

StucaNet is a construction system consisting of the StucaNet panel and the specific PlasterWall mortar: a pre-perforated cardboard sheet is “woven” into the weft of the mesh, making it ideal for the direct application of the thin layer of plaster.

NO PREPARATION OF THE APPLICATION SUPPORT: thanks to the presence of the pre-perforated cardboard sheet within the weft of the mesh, the system is ideal for use in the presence of supports with large "empty areas" resulting from shatter and falling of the hollow-core infill blocks. The plaster is applied directly on the cardboard, which acts as a "disposable formwork", avoiding the need to prepare the support.

VERSATILE and IDEAL FOR ALL TYPES OF SLABS, the system adapts perfectly to the various types of slabs (brickwork, SAP, Varese, etc…), thanks to the range of structural and non-structural fastenings.

THE SYSTEM IS LOAD SAFE AND CERTIFIED when subjected to ceiling shatter and falling load up to 300 kg/m2 with various anchor point distribution patterns and in the presence of suspended loads (lighting systems and other accessories) up to a maximum of 50 kg per individual suspension point.

FIRE RESISTANT: the StucaNet system is certified REI 240 for applications on the intrados (lower side) of 20+4 cm thick concrete beam and block floor (slab made of concrete joists and infill blocks or bricks).

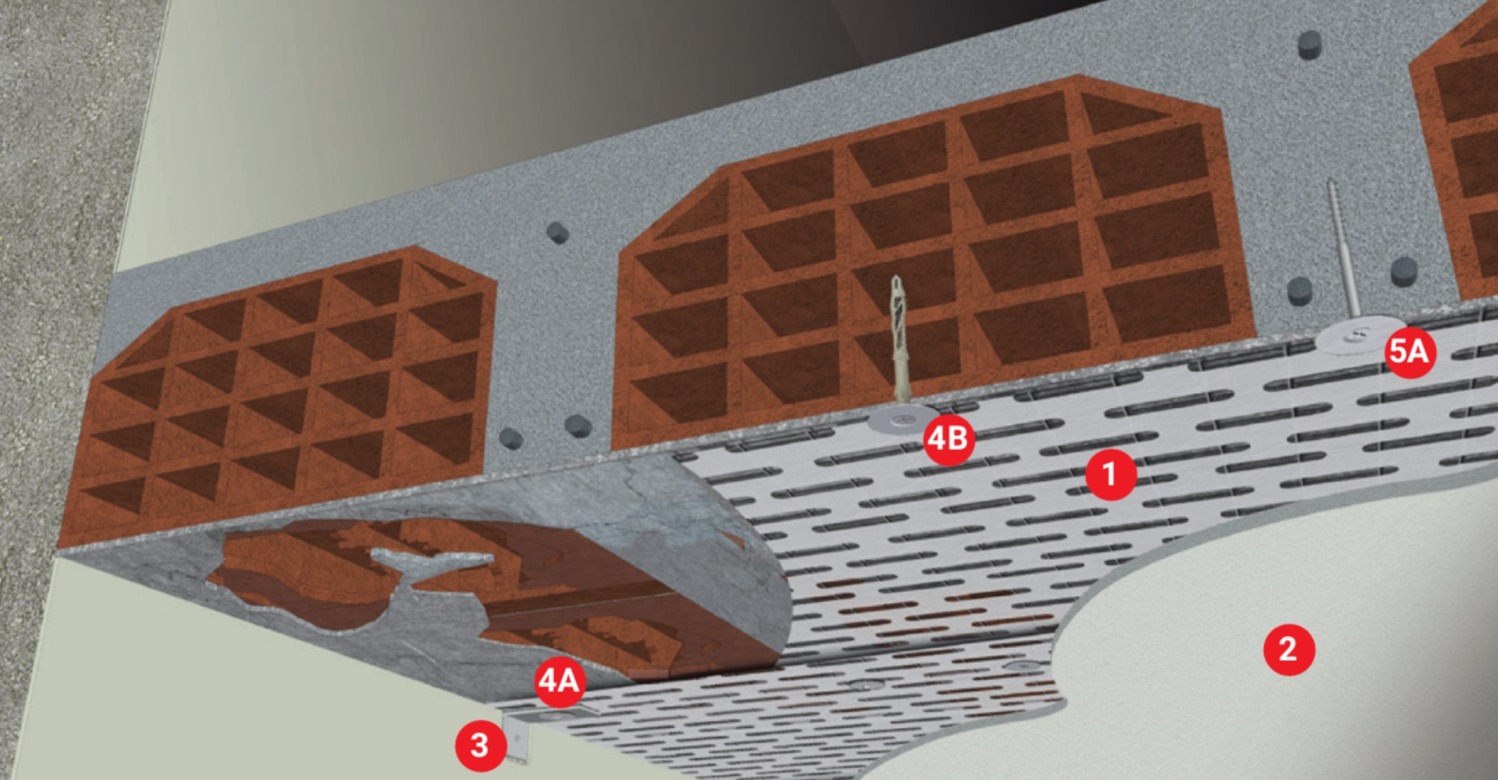

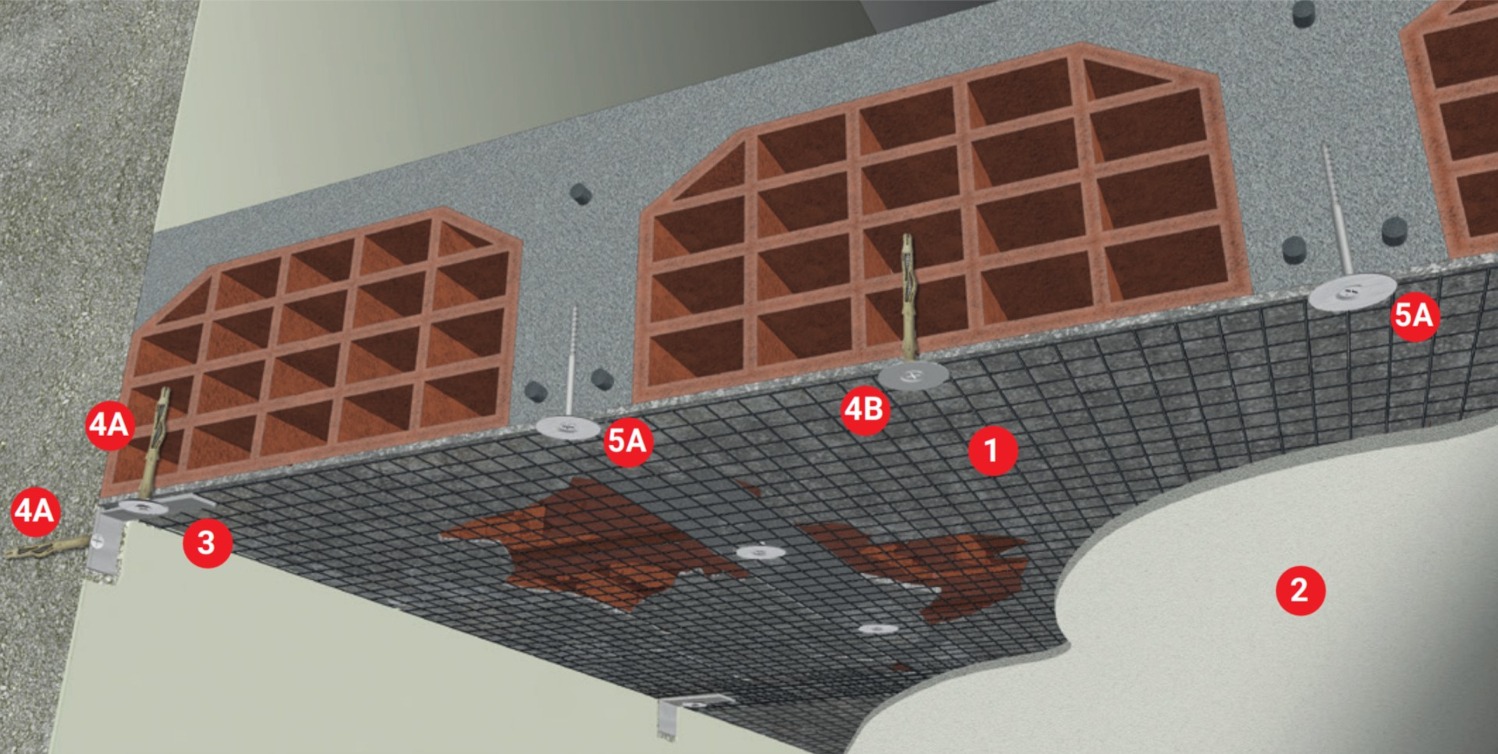

SYSTEM COMPONENTS

1 – StucaNet high galvanised steel mesh with cardboard insert

2 – PlasterWall lightweight, fibre-reinforced premix

3 – Angular plate "L" shaped for perimeter securing Stucanet mesh, applied using nylon anchors (structurally securing the mesh around the perimeter avoids the need for Angular plates).

4 – Nylon expansion anchor, equipped with a dedicated, dual-application washer:

4A – fastening the Angular Plate

4B – non-structural fastening of StucaNet

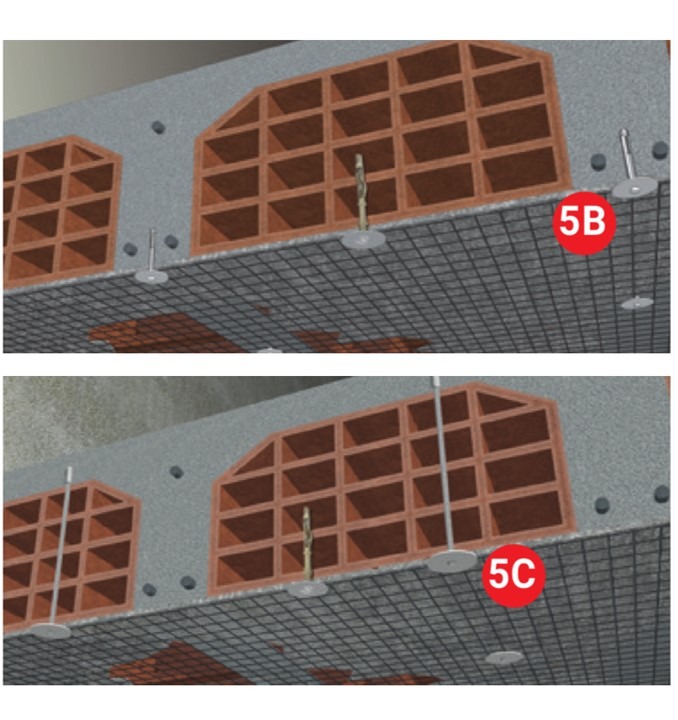

5A – Steel concrete screw, supplied with washer, for structurally fastening StucaNet in the concrete joist

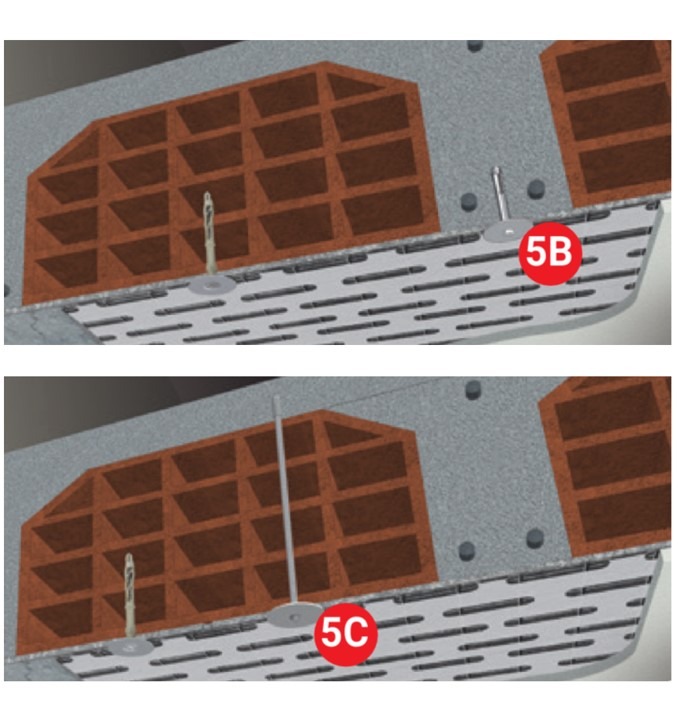

5B – Steel concrete anchor, supplied with washer, for structurally fastening StucaNet in the concrete joist.

5C – Steel concrete anchor, supplied with threaded rod, washer and self-locking nut for structural fastening StucaNet in the slab cover

THE ARMANET SYSTEM

The TRADITIONAL SYSTEM with galvanised mesh that may also be dry-laid

ArmaNet is easy to install: simply position the mesh on the intrados (lower side), anchor it using one of the structural fastening systems, securing the perimeter with the angular plate and finish with SafePlaster premixed plaster.

THE SYSTEM IS LOAD SAFE AND CERTIFIED when subjected to ceiling shatter and falling load up to 130 kg/m2, with various anchor point distribution patterns and in the presence of suspended loads (lighting systems and other accessories).

VERSATILE and IDEAL FOR ALL TYPES OF SLABS, the system adapts perfectly to the various types of slabs (brickwork, SAP, Varese, etc…), thanks to the range of structural and non-structural fastenings.

MAY ALSO BE DRY-LAID: as a preventive measure, the ArmaNet system may be applied dry or left exposed. Installation is simple and quick, guaranteeing ceiling shatter and falling load performance of up to 130 kg/m².

SYSTEM COMPONENTS

1 – ArmaNet, electrowelded, galvanised steel wire mesh

2 – SafePlaster, fibre-reinforced, reduced shrinkage premix

3 – Angular plate "L" shaped for perimeter securing ArmaNet mesh, applied using nylon anchors (structurally securing the mesh around the perimeter avoids the need for angular plates).

4 – Nylon expansion anchor, equipped with a dedicated, dual-application washer:

4A – fastening the Angular Plate

4B – non-structural fixing of ArmaNet

5A – Steel concrete screw, supplied with washer, for structurally fastening ArmaNet in the concrete joist

5B – Steel concrete anchor, supplied with washer, for structurally fastening ArmaNet in the concrete joist.

5C – Steel concrete anchor, supplied with threaded rod, washer and self-locking nut for structural fastening ArmaNet in the slab cover

Ruregold ceiling anti-shatter protection systems technical specifications

CEILING ANTI-SHATTER MESHES

AR fibreglass mesh.

Grammage: 240 g/m2

Mesh: 25×25 mm

Package: 1 m H, 50 m L rolls

Ceiling shatter and falling load:

• 500 kg/m2 (installation with SafePlaster)

• 250 kg/m2 (dry installation)

Electrowelded, galvanised steel wire mesh

Mesh: 19×19 mm, ø 0.65 mm

Package: 1 m H, 50 m L rolls

Ceiling shatter and falling load:

130 kg/m2 (dry laying)

Highly galvanised, steel wire mesh with cardboard insert.

Mesh: 38×50 mm (main direction)

38×27 mm (transverse direction)

ø 1.5 mm

Packaging: 2.40 x 0.70 m panels

Ceiling shatter and falling load:

300 kg/m2 (with PlasterWall)

CEILING ANTI-SHATTER PLASTERS

Premixed, fibre-reinforced, reduced shrinkage plaster mortar for installing SafeNet and ArmaNet systems.

Specific weight: approx. 1,850 kg/m3

Compressive strength: class CSII (1.5-5 MPa) UNI EN 998-1

Applicability:

• By machine (PFT G4 plastering machine or equivalent)

• By hand (concrete mixer, Turbomalt mixer)

Application thickness: 10 mm per coat

Yield: approx. 15.5 kg/m² per cm of thickness

Packaging: 25 kg bag on pallets of 60 bags (1500 kg)

Fibre-reinforced, lightweight premixed plaster mortar for coating the StucaNet ceiling anti-shatter protection system

Specific weight: approx. 1,650 kg/m3

Compressive strength: class CIII (≥5 MPa) UNI EN 998-1

Applicability:

• By machine (PFT G4 plastering machine or equivalent)

• By hand (concrete mixer, Turbomalt mixer)

Application thickness: 10-20 mm per coat

Yield: approx. 12 kg/m² per cm of thickness

Packaging: 25 kg bag on pallets of 60 bags (1500 kg)

FASTENINGS FOR THE 3 CEILING ANTI-SHATTER SYSTEMS

V-CLS | Concrete Screw

Steel screw, supplied with dedicated steel washer and SBR coupled, for structurally fastening SafeNet, StucaNet and ArmaNet meshes in concrete joists.

Fastening (StucaNet-ArmaNet):

• 4 pcs/m² approx. (SafeNet)

• 8 pcs/m² approx.

Screw:

• Underhead length 100 mm

• External diameter 7.5 mm

Washer: Ø 50 mm

Maximum fastening thickness: 40 mm

Hole: Ø 6 mm | drill with Torx T 30 insert

Marking: ETA 17/0471

Package: box of 100 pcs

V-CLS | Concrete Screw

Steel screw, supplied with dedicated steel washer and SBR coupled, for structurally fastening SafeNet, StucaNet and ArmaNet meshes in concrete joists.

Fastening (StucaNet-ArmaNet):

• 4 pcs/m² approx. (SafeNet)

• 8 pcs/m² approx.

Screw:

• Underhead length 100 mm

• External diameter 7.5 mm

Washer: Ø 50 mm

Maximum fastening thickness: 40 mm

Hole: Ø 6 mm | drill with Torx T 30 insert

Marking: ETA 17/0471

Package: box of 100 pcs

TN | Nylon anchor

Nylon expansion anchor, supplied with a specific steel washer and SBR coupled, for non-structurally fastening StucaNet and ArmaNet meshes in slab hollow-core infill blocks.

Fastening:

2 pieces/m² approx.

Anchor: • Length 100 mm

• Outer diameter 8 mm

Washer: Ø 50 mm

Hole: Ø 8 mm | drill with Torx T 30 insert

Marking: ETA 17/0294

Package: box of 100 pcs

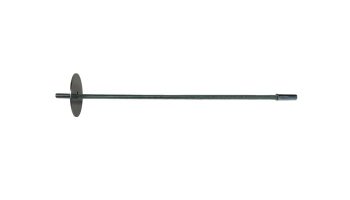

TP-CLS | Concrete through-anchor

Steel expansion anchor, supplied with threaded rod, steel washer and SBR coupled, self-locking nut for structurally fastening SafeNet, StucaNet, ArmaNet networks in the concrete top slab.

Fastening:

• 4 pieces/m2 approx. (SafeNet)

• 8 pcs/m2 approx. (StucaNetArmaNet

) Anchor: length 25 mm

external Ø 8 mm

Threaded rod: length 270 mm

Washer: Ø 50 mm

Hole: Ø 8 mm

Maximum fastening thickness: 240 mm

Marking: ETA21/0450

Package: box of 100 pcs

PA | Angular plate

“L” shaped angular plate for perimeter securing SafeNet, ArmaNet and StucaNet, meshes, applied using nylon anchors.

Fastening: 1-2 pcs/m (frc system)

Angular plate: 100 mm (slab side) x 50 mm (wall side) x 50 mm (width)

Anchor: length 100 mm

External Ø 8 mm

Washer: Ø 50 mm

Hole: Ø 8 mm | drill with Torx T 30 insert

Maximum fastening thickness: 30 mm

Packaging: box of 50 pcs

Select the ceiling anti-shatter system that best suits your needs.

At Ruregold, we have been working hand-in-hand

with designers for over twenty years and offering

our experience in the sector and our

qualified technicians to support your

calculation and design processes.