Micro-concrete

Micro-concrete reinforced with steel or synthetic fibers for the jacketing the construction of reinforcement layers for concrete elements.

Structural reinforcement

with Micro-concretes with tensile strain-hardening behavior

Fiber-reinforced micro-concretes are composite materials characterized by a cementitious matrix and discontinuous reinforcing fibers.

The matrix usually consists of a high-performance mortar or concrete, while the fibers can be made of steel, polymers or carbon.

Micro-concretes are innovative technologies that have been increasingly adopted for the repair and structural upgrade of existing structures on the basis of their residual tensile strength in the post-cracked phase.

The main advantage in the use of micro-concretes is linked to the high tensile strength that is reached in the post-cracking phase. This enables a substantial

reduction of the thickness of micro-concrete jacket compared to traditional jackets with materials with lower ductility.

The most common uses of micro-concretes for repair and structural upgrade are as follows:

- construction of thin diaphragms up to 1 + 3/16 in. (3 cm) that are cast-in-place over existing horizontal surfaces.

- construction of thin jackets (up to 1+ 9/16 in. (4 cm) thickness, over reinforced concrete frames with or without the addition of primary supplemental reinforcement.

Controlled dissipation of energy

Fiber-reinforced micro-concretes can safely increase the capacity of a concrete structural element to sustain flexural and/or shear stress beyond its elastic limits. The increased load-bearing capacity depends on the ability of micro-concrete to dissipate energy through the formation of micro-cracks, which can be considered as an experimental evidence of the energy-dissipation mechanism. The amplitude of the micro-cracks depends on the

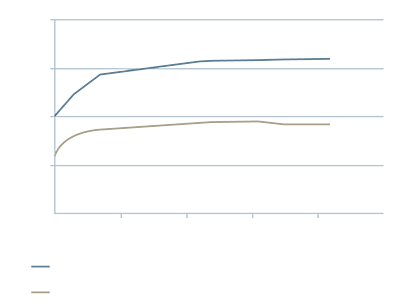

type of fiber and its quantity. The graph below shows that at a deformation of 1% the amplitude of micro-cracks stabilizes at around 80 microns for Micro Gold FCC, which is Ruregold’s micro-concrete containing structural synthetic fibers. On the other hand, the amplitude of the micro-cracks in traditional fiber-reinforced mortars (with polymeric fibers and metal fibers) exceeds 500 microns. This is a dangerous value for the durability of both concrete

and reinforcement. At 1000 microns cracks are so wide that allow the penetration of aggressive chemical and environmental agents, such as chlorides and acid rains, which can deteriorate concrete and induce corrosion in the rebars.

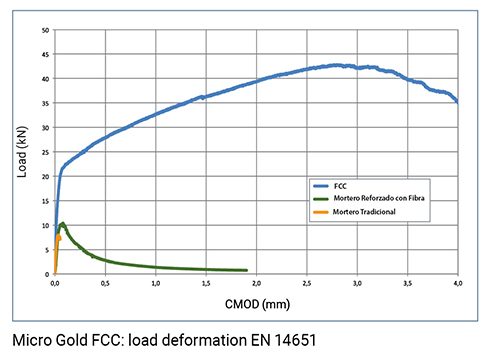

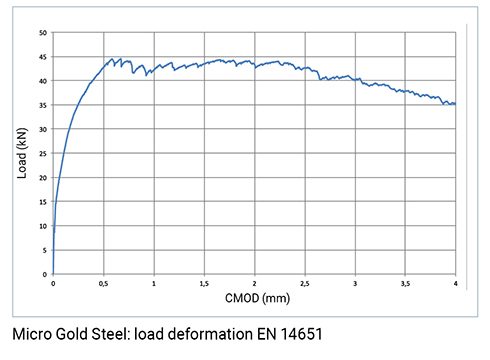

Experimental load/deformation

curves

The graphs show the load/deformation CMOD (Crack Mouth Opening Displacement) curves, according to EN 14651 standard, measured after 28-day curing. The area below the blue lines is a strong indicator of the ductility of the two Ruregold Micro Gold concretes products: Micro Gold FCC containing structural polymer fibers and Micro Gold Steel with steel fibers.

The curves on the left represent the stress-strain behavior when the products are tested for tensile strength. There is evidently a major difference between the behavior of micro-concretes and traditional fiber-reinforced mortars,

which are characterized by a softening behavior (green line), or with traditional R4 mortars which are not reinforced (yellow line) and show fragile behavior.

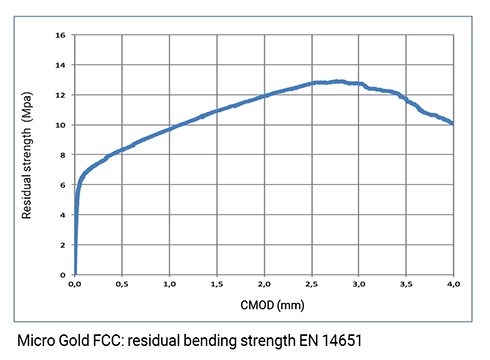

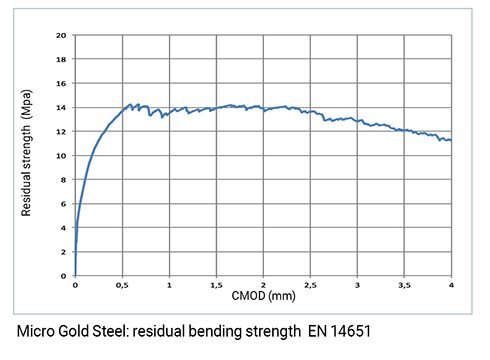

The curves on the right depict the stress-strain behavior when Ruregold micro-concretes are tested for flexural strength and the relative values of fRj, determined according to the provisions of EN 14651.1. The area underlying

the curve is evidence of the high ductility of the Ruregold products, which can be advantageously used for seismic retrofitting of reinforced concrete structures, without the addition of reinforcing bars.

The summary table below compares the residual flexural tensile strength – fRj (MPA) of the three different products.

| MICRO FCC | MICRO STEEL | ||

|---|---|---|---|

| CMOD 1= 0,5 mm | fR1 = 8,05 | fR1 = 13,75 | |

| CMOD 2= 1,5 mm | fR2 = 10,90 | fR2 = 13,90 | |

| CMOD 3= 2,5 mm | fR3 = 12,70 | fR3= 13,60 | |

| CMOD 4= 3,5 mm | fR4 = 11,60 | fR4 = 12,10 |

RESIDUAL FLEXURAL TENSILE STRENGTH – FRJ (MPA)

Request Information

Discover all the products