The new reinforcement frontier:

FRCM composite materials

Ruregold strengthening systems utilize two different types of fibers, carbon and PBO (poly-paraphenyleneben- zobisoxazole), both synthetic materials with high mechanical performance properties able to absorb the stresses generated by overloads and exceptional events, such as earthquakes. The PBO fibers, compared to carbon fibers, have tensile strength greater than 40% and elastic modulus greater than 15%.

FRCM (Fabric Reinforced Cementitious Matrix) structural strengthening systems consist of the coupling of a high performance long fiber and a stabilized inorganic matrix used as an adhesive, replacing the epoxy resins of traditional FRP systems.

Ruregold has introduced a global innovation in the field of structural reinforcements by patenting several FRCM strengthening systems, each of which has been specifically developed to meet the needs related to reinforcement and seismic retrofit of various structures, such as reinforced concrete structures, masonry structures, and infill elements.

The adhesives are formulated to match each type of mesh reinforcement system, thus ensuring effective bond to both structural fibers of the mesh and to the materials constituting the substrate, guaranteeing the high reliability of the

structural reinforcement.

Ruregold composite reinforcements use woven structural fibers with a specific geometry to guarantee greater versatility of use, that is, a greater ability to manage stresses even in the most complex load situations, such as column buckling, shear strength of panels, bending and shear of beams, and actions in the plane and outside the plane.

FRCM strengthening systems have significant benefits:

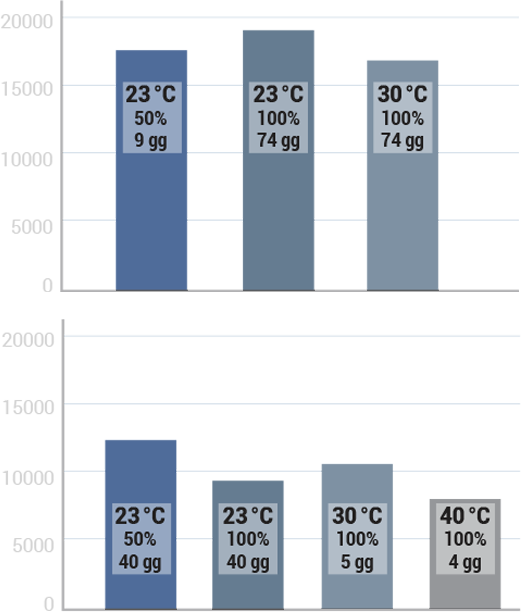

Application on damp substrates

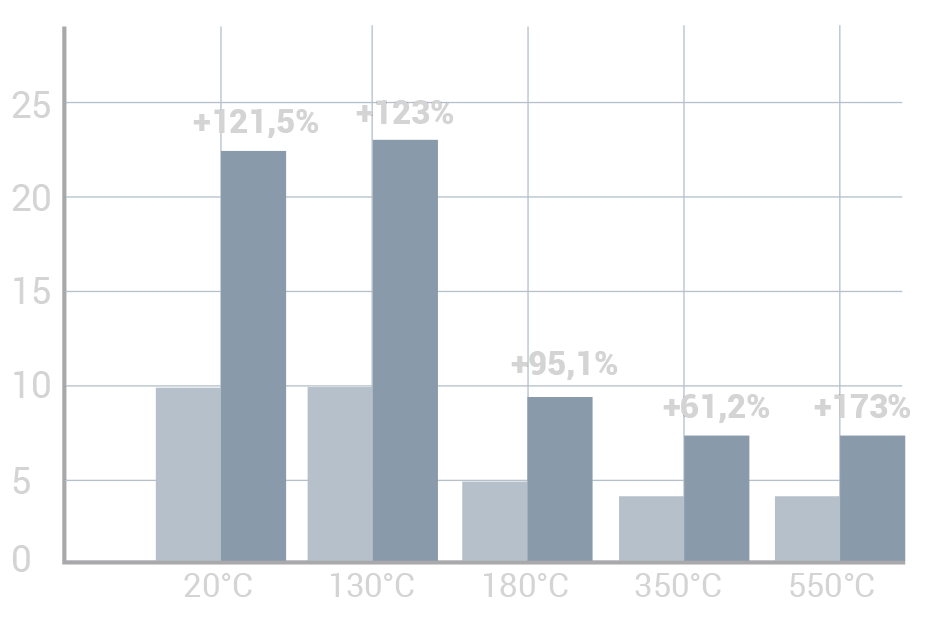

Fire resistance

Vapor permeability

Non-toxic matrix

Resistance to high temperatures

Resistance to freeze and thaw cycles

Ease of installation

Ecological

Compatible with masonry

Ductility

Passive protection

Reversible

FRCM: proven anti-seismic efficacy

Properties of Ruregold’s FRCM strengthening systems

Strengthening systems in a seismic zone are aimed at retrofitting the structure to the intensity of the expected seismic action. Composite materials are particularly suitable for this purpose since they increase the ductility of the structural elements they reinforce. In addition they are easy to apply, which allow applications in critical areas that may

be difficult to reach, especially in case of historic masonry.

The strategy of seismic retrofit interventions is aimed at eliminating the brittle fracture mechanism of load-bearing structural elements and the collapse mechanisms in correspondence of the joints, as well as at improving the overall deformation capacity of the structure.

In reinforced concrete structures this requirement

is mainly obtained by increasing the ductility of the plastic hinges. In masonry structures, the key procedure is box action of load-bearing masonry elements so as to make them more resistant to horizontal actions, eliminate the orthogonal thrusts to the wall panels and connect the perpendicular load-bearing elements to each other.

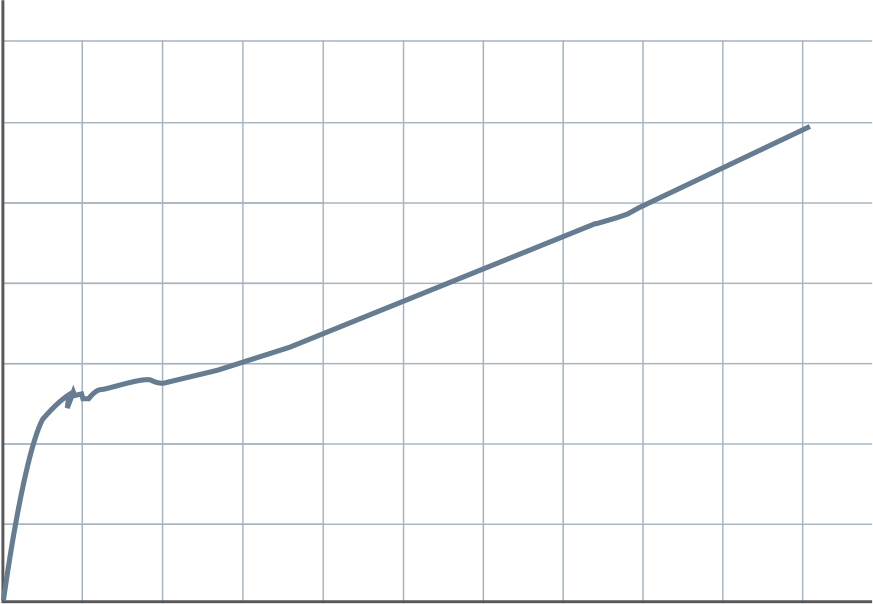

The deformation capacity of the reinforcing element

and the adhesion of the reinforcement to the structure are of fundamental importance for the effectiveness and reliability of FRCM seismic retrofit. Ruregold’s FRCM systems assure these characteristics even in extreme conditions, when cracks are forming in the support.